About

the Project About

the Project

The Need for Beach Replenishment

The standard of flood and coast protection at Poole Bay depends mainly on the

level and width of its beaches.

During the 20th Century the cliffs were protected from

erosion by building concrete seawalls, promenades and groynes. This

allowed houses to be built on the cliff tops, but it also stopped the natural

supply of sand and gravel to the shore.

Bournemouth beach has been

replenished on four previous occasions in the last 36 years and is now

effectively an artificial beach. Those projects are called 'Beach

Improvement Schemes' (BIS):

|

Scheme |

Year |

Quantity of sand (m3) |

|

BIS1 |

1970 |

84,000 |

|

BIS2 |

1974-75 |

1,400,000 |

|

BIS3 |

1988-89 |

1,000,000 |

|

BIS4.1 |

2005-6 |

600,000 |

|

BIS4.2 |

2006-7 |

898,000* |

|

*includes 15,000m3 stockpiled for the

surf reef |

|

BIS4.1 was part of last

winter's project using material dredged from Poole Harbour. The quantity

of sand available was insufficient to replenish the entire beach so work

continued during winter 2006/07 (BIS4.2).

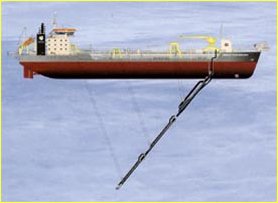

The sandy material used for BIS4.2 was

transported by the Oranje from a Licensed Dredging Area to the east

of the Isle of Wight. The dredger came in as close as possible to

the beach but the waters of Poole Bay are shallow and the material was pumped ashore through a 1150m long pipe known as a

'sinkerline' which connected the dredger with the beach.

The sinkerline was constructed locally, at

Branksome Chine on the Poole/Bournemouth boundary.

Bournemouth

beach is interrupted by high level timber groynes, but the replenishment

at Poole last winter created a wide, flat beach with the old groynes

buried below sand. The conditions at Poole were ideal for fabricating

and welding the pipework. Once completed, the sinkerline stretched from Branksome Chine to

Flaghead Chine; small sand ‘bridges’ were created

during fabrication to allow public access to the shoreline until it was

moved offshore and towed to Bournemouth.

Sinkerline facts...

-

Each section of sinkerline is 18m long, 1.1m in diameter and weighs 13 tonnes

-

The

steel that makes up the sections is 1" thick

-

The sections are so heavy that only two could be transported from the docks to the beach at one

time

-

The

sinkerline was last used on a replenishment project in Africa The

sinkerline was last used on a replenishment project in Africa

How the sand gets to the beach

The sinkerline was towed to a position between Bournemouth and Boscombe

piers. With one end at the shoreline and the other out at sea, it

was sunk to the seabed.

At the seaward end the sinkerline is coupled to a flexible riser pipe

section and flexible floating pipeline. During operations the

multicat (support vessel) Zwerver II takes care of

the floating section and connects it to the loaded dredger when she

arrives at the Bournemouth coast via a bespoke coupling ball-joint system.

At the landward end the sinkerline is fitted with a steel flange from

which sections of onshore pipeline (approximately 12m long) can be coupled to

discharge sand to the required locations.

Sand is mixed with a considerable amount of water in the dredger's hopper to assist it being

pumped through the 1,150m sinkerline and along the onshore pipeline.

On the beach horseshoe-shaped sand bunds are formed; the sand/water

mixture is pumped into these bunds and they act to retain the new sand on

the beach avoiding losses to the foreshore. Sand settles on the

beach and water returns to the sea. The settled sand is levelled by

bulldozer

and new sections are added to the onshore pipeline in preparation for the

next load. In this way replenishment work moves along the beach.

Measuring quantities pumped

ashore

There are two factors to take into account when estimating

the quantity of sand reaching the beach. The amount we refer to as

"pumped ashore" is recorded by the dredger and we have to allow for a

'bulking factor' of 1.2 due to the sand being mixed with water in the

hopper. For instance, if 10,000m3 is recorded has having been pumped

from the hopper it would equate to about 8,333m3 material actually

arriving at the beach.

We then allow

for up to 15% of that 8,333m3 being lost to the foreshore during pumping &

draining, so only 7,100m3 might be left on the beach. Losses can

depend on the weather; the stormier the conditions, the larger the losses

are likely to be.

These figures

provide guidelines. Beaches are independently surveyed on a daily

basis, comparing levels and widths to a baseline survey carried out before

work commenced; in that way we get an accurate picture of how much sand

has actually been delivered. Westminster Dredging were contracted to

replenish the beaches by a minimum of 700,000m3 not simply to pump 700,000m3, so the

amount recorded as pumped (e.g. the amounts mentioned in

our

project diary) actually totalled more than 1 million m3. our

project diary) actually totalled more than 1 million m3.

In the interests of health & safety it was

necessary to close short lengths of beach while sand was being pumped

ashore by the dredger and being moved by bulldozers. The promenade remained open at all times.

Initially the new sand appeared darker than that

already on the beach but soon lightened to a normal colour with exposure

to oxygen and daylight. In the first few weeks small ledges

appeared in the beach as wave action sorted the new sand into a natural

beach profile. The beach was regularly inspected for any unsuitable

material.

About the Oranje

|

|

A trailing suction

hopper dredger |

To

give her full title the Oranje is a trailing suction hopper dredger

(or TSHD). She trails a suction pipe on the seabed and loads

sand into an open hopper. When the hopper is full she raises the

suction pipe and sails to the seaward end of the sinkerline at

Bournemouth. She is coupled with the floating section of the pipe

and the sand is pumped from the hopper on to the beach.

Built in Holland in 2004 for

Royal Boskalis Westminster, at 156m long Oranje is 60m longer

than any of the dredgers that worked on the replenishment project last

winter - and as long as the Barfleur. Her hopper capacity is almost

16,000m3 - about 4x that of last year’s vessels and she’s

quicker too, with a top speed of 16.2 knots.

The number of loads brought to

the shore was much reduced on the previous phase due to the distance

the Oranje travelled between dredging and pumping ashore.

Last winter we averaged 5 loads per day; for this project just one or two

loads were delivered in a 24 hour period with an approximate ‘turnaround time’ of 10 hours.

|

Bournemouth’s existing timber groynes will last another 8 years or

so, after which consideration will be given as to what should

replace them; perhaps rock groynes or offshore reefs.

In the past Bournemouth beach has been

replenished at intervals of 15 years or so, by which time most of

the sand has been lost. For the next 3 years small scale

top-ups will be used to keep the volume high. |

|